Home » PP Thin Wall

What is PP Thin Wall Injection Molding?

The wall thickness of traditional injection molded products typically ranges from 2.5mm to 4mm. Thin-wall injection molding is generally defined as a process where the wall thickness is less than 1.5mm. PP, due to its excellent flowability, can push this standard even further, even enabling designs with wall thicknesses below 0.6mm.

A key metric for thin-wall injection molding is the flow length to wall thickness ratio (L/T). A higher ratio means the molten plastic needs to flow through a longer and thinner path, placing more stringent requirements on materials and processes.

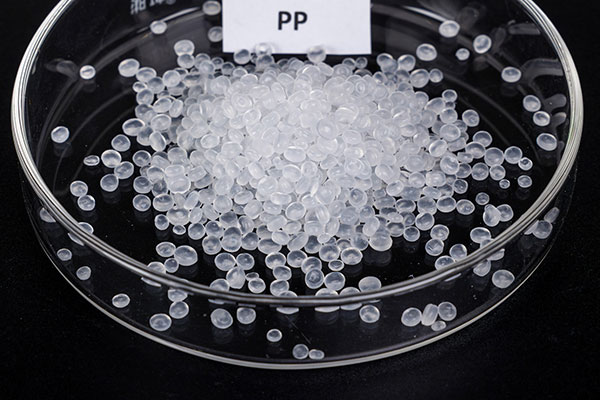

Hot Sale PP Thin Wall Granules in Our Company

Would Like The Quotation

Leave more about your requirements, such as, brands, models, quantity, package, country, etc.

Why choose PP?

Excellent flow properties. High-performance, high-melt-index PP material flows extremely well in the molten state, quickly filling complex and narrow mold cavities and ensuring complete molding of thin-walled products.

High rigidity and high impact strength. While reducing wall thickness, it is crucial to maintain structural strength and resistance to drops and impacts. Through copolymerization and other methods, PP can maintain excellent mechanical properties even in thin-walled applications.

Lightweight. The most direct effect of reducing wall thickness is a significant reduction in product weight, meeting the strong demand for weight reduction in areas such as electronics and automotive components.

Cost-effectiveness. PP is a highly cost-effective general-purpose plastic. Using less material per product not only reduces material costs but also shortens cooling time, improves production efficiency, and further reduces overall manufacturing costs.

Environmental protection and recyclability. PP is non-toxic and odorless, meets food contact standards, and is 100% recyclable, aligning with the global trend toward a circular economy.

Main applications of PP Thin Wall Grade

Food packaging: Disposable lunch boxes, yogurt cups, jelly cups, fast food containers, etc. This is the most traditional and largest market for thin-wall injection molding, requiring hygiene, lightness, and durability.

Electronic appliances: Mobile phone cases, laptop battery covers, charger cases, thin-wall cable reels, etc. While maintaining structural strength, this achieves product thinness.

Household items: Thin-wall storage boxes, organizers, water cups, etc. are lightweight and aesthetically pleasing.

Medical devices: Disposable test tubes, culture dishes, medicine cups, etc., take advantage of their sterilizability and disposable properties.

Automotive industry: Automotive interior components, such as panels, trims, and storage boxes, help reduce vehicle weight and energy consumption.

- Email: sales@chemategroup.com

- Tel: 0086-371-60921621

- Whatsapp: +86 18624832876

- Wechat: +86 18624832876

- ADD: NO.80 PUHUI ROAD,ZHENGZHOU CITY, HENAN PROVINCE, CHINA