Home » Caustic Soda for Sale

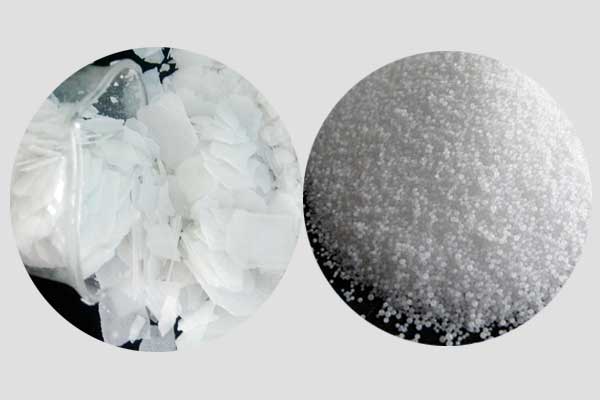

Caustic Soda Flakes/Pearls 99%

- CAS NO.: 1310-73-2

- HS Code: 2815110000

- MF: NaOH

- Sodium hydroxide content: 99%

- Appearance: Flakes, Pearls( Particle size:≤ 0.8 mm 8%max, 0.8-1.2 mm 90%min, ≥1.2 mm 2%max)

- Package: 25kgs plastic woven bags double lined with polythene bags. 1200kg jumbo bags.

Caustic soda for sale in our company is with 99% content of sodium hydroxide and less impurities, so it can meet your various requirements in the varieties of industrial fields. Contact us to get the price of sodium hydroxide for sale in Chemate now.

Specifications of Caustic Soda for Sale in Our Company

| Items | Caustic Soda Flakes | Caustic Soda Pearls |

| Sodium Hydroxide %≥ | 99 | 99 |

| Sodium Carbonate%≤ | 0.5 | 0.5 |

| Sodium Chloride %≤ | 0.03 | 0.03 |

| Ferroso-ferric Oxide %≤ | 0.005 | 0.005 |

| Particle size | —– | ≤ 0.8 mm 8%max |

| 0.8-1.2 mm 90%min | ||

| ≥1.2 mm 2%max | ||

| Packing | 25kgs plastic woven bags double lined with polythene bags. 1200kg jumbo bags. | |

| Storage | They should be stored in a dry, ventilative and clean warehouse, kept away from water and moisture, furthermore, they should be stored separately from poisonous. | |

Would like The Quotation?

Leave your demands in detail here(including the model, package, brand, quantity), we will reply you quickly.

What Is Caustic Soda Used for

Customers usually call this chemical caustic soda flakes, caustic soda pearls, liquid caustic soda when purchasing sodium hydroxide products suitable for their own industrial fields. The most common use of sodium hydroxide is the production of pharmaceutical chemicals, followed by papermaking, aluminum smelting, tungsten smelting, rayon, artificial cotton and soap manufacturing industries. In addition, a large amount of sodium hydroxide is also used in the production of dyes, plastics, pharmaceuticals and organic intermediates, the regeneration of old rubber, the production of metal sodium, the electrolysis of water, as well as the production of inorganic salts.

For indigo dyes and quinone dyes. During the dyeing process of vat dyes, it is first reduce to leuco acid with caustic soda solution, and then oxidize it to the original insoluble state with oxidizing agent after dyeing. After treating the cotton fabric with lye sodium hydroxide, it can remove the wax, grease, starch and other substances covering the cotton fabric, and at the same time can increase the mercerized color of the fabric and make the dyeing more uniform.

Treat cotton and linen textiles with concentrated caustic soda solution to improve fiber properties. Man-made fibers are mostly viscose fibers, which are made by using cellulose as a raw material to make viscose liquid, spinning and coagulating.

To make viscose fiber, firstly use 18%-20% sodium hydroxide solution to impregnate the cellulose to make it into alkali cellulose, then dry and crush the alkali cellulose, and finally dissolve the sulfonate with dilute lye to obtain viscose liquid. After filtering and vacuuming, it can be used for spinning.

Caustic soda is soluble in ethanol and glycerin, insoluble in propanol and ether, and has relatively high solubility in water. It has strong alkalinity, so it is usually as an alkaline cleaning agent in water treatment. Caustic soda will also corrode sodium carbonate at high temperatures. It has a disproportionation reaction with chlorine, bromine and iodine, and can neutralize acid to form salt and water. Caustic soda mainly contains hydroxide and sodium ions. Among them, hydroxide can combine with many kinds of metal ions to form flocs or precipitates, thereby eliminating heavy metal ions in the water. In wastewater treatment, sodium hydroxide can reduce the hardness of water through neutralization reaction and adjust the pH value of water. It is also a regenerating agent for ion exchange resin regeneration.

The raw materials for papermaking are wood or grass plants. In addition to cellulose, these plants also contain a lot of non-cellulose, such as lignin and gums. Sodium hydroxide is used to remove lignin, carbohydrates and resins from wood to obtain fiber. The addition of dilute sodium hydroxide solution can dissolve and separate non-cellulose components, thereby preparing pulp with cellulose as the main component.

Widely used in the production of soap, toilet soaps and other kinds of detergents. In the process of making soap, the use of caustic soda can neutralize fatty acids. Adding lye sodium hydroxide to the solution can reduce the solubility of the fatty acid salt to separate the fatty acid salt. Higher fatty acid salt is the main component of soap. In addition, washing powder is also made from a large amount of caustic soda, which is used to neutralize excess fuming sulfuric acid after the vulcanization reaction.

In order to remove the colloid in the petroleum fraction, concentrated sulfuric acid is generally added to the petroleum fraction to make the colloid become acid residue and precipitate. After pickling, the petroleum still contains acidic impurities such as phenol, naphthenic acid and excess sulfuric acid, which must be washed with sodium hydroxide solution. And then washed with water to obtain refined petroleum products. It can also be used in oilfield drilling mud.

In order to remove the insoluble impurities, the active ingredients in the ore usually need to be converted into soluble sodium salts. Therefore, it is often necessary to add soda ash or sodium hydroxide as fluxing agent.

Caustic soda is used to make metallic sodium and electrolyzed water. The production of many inorganic salts, especially the preparation of some sodium salts, such as borax, sodium silicate, sodium phosphate, sodium dichromate, sodium sulfite, requires sodium hydroxide and soda ash. The two chemicals are also used in the synthesis of dyes, drugs and organic intermediates.

Used for dredging sewers, cleaning range hoods, etc. The main component of the plumbing agent is sodium hydroxide, which is a strong base and has the effect of decomposing protein.

Food grade sodium hydroxide can be used as acid neutralizers, used as peeling agents for citrus, peaches, etc. It can also be used as the detergent for containers, such as empty bottles and cans, as well as decolorant and deodorant. Also be used in the preparation of starch, carboxymethyl cellulose and sodium glutamate.

Would like The Quotation?

Leave your demands in detail here(including the model, package, brand, quantity), we will reply you quickly.

Know More About Caustic Soda

Caustic soda, with the scientific name of sodium hydroxide and chemical formula of NaOH, contains three forms, caustic soda flakes, caustic soda pearls, liquid caustic soda in appearance. Sodium hydroxide is highly alkaline and highly corrosive, so it can be used as alkaline cleaning agent in water treatment. Meanwhile, it can also be as an acid neutralizer, compounding masking agent, precipitating agent, developer, saponifier, peeling agent, detergent builder, etc.

They are essentially the same, the main ingredient are both sodium hydroxide. From the appearance, caustic soda pearls are granular, while caustic soda flakes are flaky. The pearl type is uniform in size, so it dissolves faster and weighs more easily. In addition, the production process of pearl type is more complicated and the price is higher. Customer can choose the type that suits them according to their uses and requirements.

There are two methods for production of caustic soda, causticizing method and electrolysis method. Divide causticization method into soda ash causticization method and trona causticization method according to different raw materials. And divide electrolysis method into diaphragm electrolysis method and ion exchange membrane method.

Soda ash causticization method

The soda ash is made into a soda ash solution, and lime is made into a lime milk. Then carry out the causticizing reaction at a temperature of 99~101℃. Clarify, evaporate and concentrate causticizing liquid to more than 40% to obtain liquid caustic soda. Then the concentrated liquid is further concentrated and solidified to obtain a solid caustic soda product.

Trona causticization method

Crush, dissolve, and clarify the trona, then add with lime milk, and causticize at 95-100℃. Then clarify, evaporate and concentrated the causticizing liquid to a concentration of about 46%. Cool and salt out the clear liquid, and then further boil it to obtain solid sodium hydroxide.

Diaphragm electrolysis method

After melting the original salt, add soda ash, caustic soda, and barium chloride refined preparations, remove impurities such as calcium, magnesium, sulfate ions. Then add sodium polyacrylate or causticized bran to the clarification tank to accelerate the precipitation. Add hydrochloric acid after filtration to neutralize, preheat the brine and then send it to electrolysis. Preheat, evaporate, salt, and cool the electrolyte to prepare liquid caustic soda, which is further concentrated to obtain solid product.

Ion exchange membrane method

This method uses the ion exchange membrane method to electrolyze salt water, and then produce sodium hydroxide. The main principle is that the cation exchange membrane used has special selective permeability. That is, only H+ and Na+ are allowed to pass, but Cl-, OH-, the bipolar products H2 and Cl2 can’t pass. Therefore, it plays a role in preventing the mixing of the anode product Cl2 and the cathode product H2. It also plays a role in avoiding the reaction of Cl2 and NaOH, another product of the cathode. And then generate NaClO and affect the purity of caustic soda.

Why Choose Caustic Soda Supplier - Chemate

With more than 15 years of experience in exporting chemical products, our chemicals have been exported to many countries and regions all over the world, such as Israel, Malaysia, Vietnam, Thailand, Syria, Turkey, Pakistan, India, Russia, Brazil, Romania, Saudi Arabia, etc. Because of the high quality and competitive price of the chemicals we provide. The brand of Chemate has won a good reputation in foreign markets. Inquiry us for the price of caustic soda for sale in our company now, we will reply you in 24 hours.

- Email: sales@chemategroup.com

- Tel: 0086-371-60921621

- Whatsapp: +86 18624832876

- Wechat: +86 18624832876

- ADD: NO.80 PUHUI ROAD,ZHENGZHOU CITY, HENAN PROVINCE, CHINA