Home » Toluene Diisocyanate

What Is TDI Chemical

- Molecular formula:C9H6N2O2

- CAS No.:26471-62-5

- HS Code: 29291020

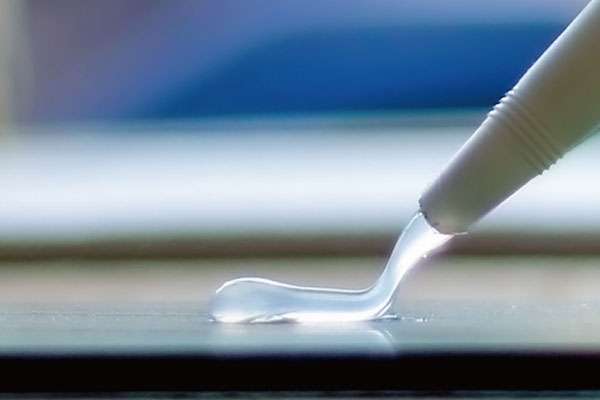

- Appearance: Colrless to Light yellow liquid

Toluene Diisocyanate(TDI) is an organic compound. It has six possible isomers, but only 2,4-TDI and 2,6-TDI are of commercial importance. Commercial available TDI chemical is usually an 80/20 mixture of the 2,4-TDI and 2,6-TDI. It is a volatile colorless to pale yellow transparent liquid in appearance with a pungent odor. The liquid should be kept in airtight containers under an inert atmosphere, protected from light and moisture. TDI liquid is insoluble in water and miscible with most common organic solvents. When heated to decomposition, toluene diisocyanate emits fumes of cyanide and nitrogen oxides.

Technical Specifications of Toluene Diisocyanate in Chemate

| Items | Toluene Diisocyanate |

| Appearance | Colorless to Light yellow liquid |

| Purity % ≥ | 99.50 |

| Relative Density | 1.2244 |

| Isomeric ratio% (2,4/2,6) | 80/20±1.0 |

| Hydrolyzable chlorine ppm< | 80 |

| Acidity (on HCL basis) ppm< | 30 |

| Color (APHA)< | 25 |

| Packing | 250KG Iron drum |

Would Like The Quotation

Leave more about your requirements, such as, tech grade or food grade, quantity, package, country, etc.

What Is Toluene Diisocyanate Used For

As an important chemical raw material, TDI liquid is widely used in the production of flexible polyurethane foam and other polyurethanes, such as, elastomers, polyurethane coatings, polyurethane adhesives, polyurethane waterproof materials, detergents, thickeners, antioxidants, modifiers, sprays, insulating materials, synthetic leather, paints, etc.

Organic isocyanates are widely used intermediates organic synthesis, especially the raw materials for the synthesis of polyurethane materials with excellent properties. Ad the second largest variety of organic isocyanate, TDI chemical will have a broad market prospect and development potential.

More About Toluene Diisocyanate TDI

There are three production methods of TDI chemical, amine phosgenation method, nitro compound carbonylation method and dimethyl carbonate method.

Dimethyl Carbonate Method

It is a method for producing toluene diisocyanate by substituting phosgene with dimethyl carbonate. DMC is used instead of phosgene under mild reaction conditions to synthesize 2,4-tolune dicarbamate(TDC) with 2,4-diaminotoluene (TDA). And then TDC is decomposed to obtain TDI. In the reaction, only methanol is the by-product, which is the raw material for the synthesis of DMC. Therefore, if combined with the DMC production process, the process is expected to become a “zero emission” green chemical production process.

Phosgenation Method

The production of TDI by phosgenation mainly includes five processes.

- Carbon monoxide and chlorine react to generate phosgene.

- Toluene reacts with nitric acid to generate dinitrotoluene (DNT).

- DNT reacts with hydrogen to generate toluene diamine (TDA) and water.

- The processed dry TDA reacts with phosgene to generate TDI.

- Purification of TDI.

Wherein the fourth step is a key part. General industrial production adopts two-step method of cold phosgenation and thermal phosgenation.

Carboxylation Method

Carboxylation is a relatively promising method in the generation of TDI chemical. This method uses dinitrotoluene, CO and fatty alcohols as raw materials, and uses carbonylation catalysts such as chromium, rhodium, and palladium. The early carboxylation method used precious metal catalysts, the formation conditions were harsh, and the catalysts were difficult to look back. Later, SeO2 was used as a catalyst, LiOH and acetic acid were added, and the reaction was carried out with the participation of ethanol. Under relatively mild conditions, the conversion rate of dinitrotoluene in this method can reach 100%, and the catalyst can be recovered. The relative investment cost is low.

- Toluene diisocyanate is a dangerous and highly toxic chemical, belonging to Class A, and requires a hazardous chemical business license.

- Toluene diisocyanate has a strong irritating odor, accumulates and stays latent in the human body, and has a strong irritating effect on the skin, eyes and respiratory tract.Inhalation of high-concentration toluene diisocyanate vapor can cause bronchitis, bronchopneumonia and pulmonary edema.

- Contact of liquid with skin may cause dermatitis. Liquid contact with eyes can cause severe irritation which, if left untreated, may result in permanent damage.Long-term exposure to toluene diisocyanate can cause chronic bronchitis.

- Persons exposed only to toluene diisocyanate vapor pose no risk of secondary contamination.People whose clothing or skin has been contaminated with liquid toluene diisocyanate can re-contaminate others through direct contact or through exhausted vapors.

- At room temperature, toluene diisocyanate is a clear, pale yellow liquid with a strong pungent odor.It is only flammable at high temperatures, but burning produces toxic gases (cyanides and nitrogen oxides). It is volatile and can produce toxic concentrations at room temperature. The odor of toluene diisocyanate does not provide sufficient warning of hazardous concentrations.

- According to the area affected by liquid flow and vapor diffusion, design warning area. Evacuate irrelevant personnel from the sidewind and upwind to the safe area.

- It is recommended that emergency personnel wear positive pressure self-contained air breathing apparatus and wear protective clothing.

- All equipment used while working should be grounded.

- Don’t touch broken containers and spills without putting on appropriate protective clothing.

- Cut off the source of the leak as much as possible.

- Prevent spills from entering bodies of water, sewers, basements or confirmed spaces.

- Disposal with water is strictly prohibited.

- Small spills. Cover spill with dry sand or other non-combustible material.

- Large amount of leakage. Construct dikes of dig pits for containment. Use a pump to transfer to a tank car or a special collector.

Effects of raw material supply. The impact of the shortage of energy supply and the rise of upstream natural gas prices will lead to an increase in costs and a sharp rise in prices. Raw materials of TDI liquid mainly include sulfuric acid, toluene, nitric acid, chlorine, xylene, metallurgical coke, butyl acetate and 1,1,1-trimethylol internal alkanes, etc.

Impact of demand. Products prepared using TDI mainly include polyurethane resin, anodic electrophoretic paint, polyurethane foam, water-soluble polyurethane resin and polyurethane varnish. When demand is low and supply is plentiful, price will fall.

In addition, it will also be affected by some force majeure factors, such as weather, etc.

As one of the leading toluene diisocyanate manufacturers in China, Chemate can guarantee sufficient product supply, high quality, competitive price and excellent toluene diisocyanate price. Have any need? Feel free to inquiry us now for quotation.

- Email: sales@chemategroup.com

- Tel: 0086-371-60921621

- Whatsapp: +86 18624832876

- Wechat: +86 18624832876

- ADD: NO.80 PUHUI ROAD,ZHENGZHOU CITY, HENAN PROVINCE, CHINA